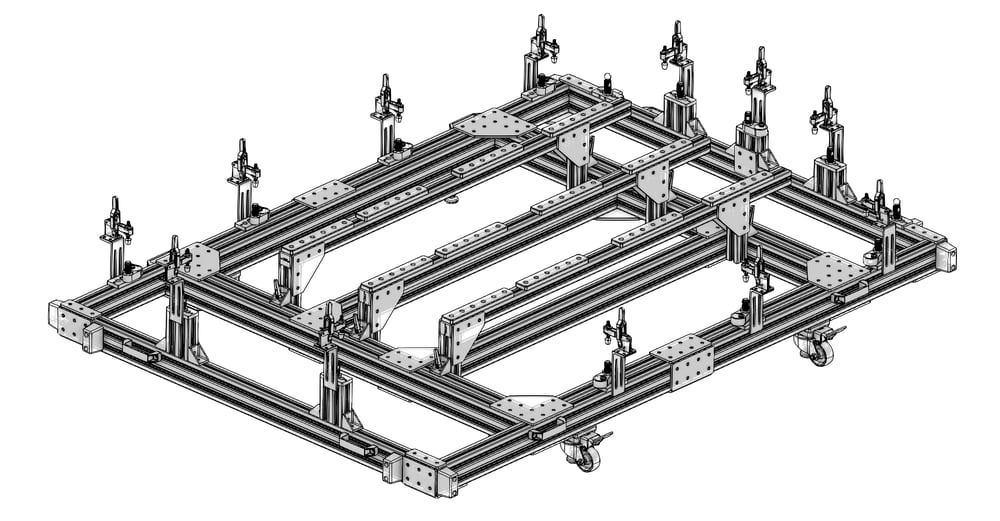

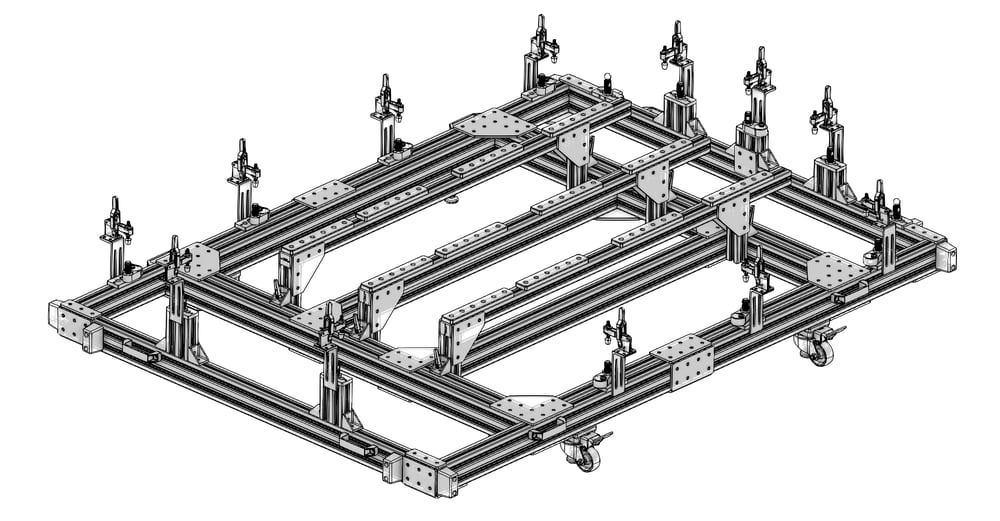

Along with our experiences we have taken into consideration our customers requirements and their commonly held standard practices for. Base plate must fully encapsulated the part and any swing out details in their fully opened position.

What Is Jig Fixture Design Carr Lane Mfg Co

Up to 24 cash back Checking fixture design guidelines.

. Graphic Design Guidelines Downtown Design. Check Fixture Tooling Standards This Gage Standard is designed as a guide for the design and building of checking gages suitable for our products this guideline is to be considered as a minimum requirement. The design should consider the safety of the operator and the workpiece too.

Design Principles Fixture should be designed to have the least mass possible Weight limits on shaker table Fixture should be designed to be as stiff as possible No unnecessary vibrations Ensure natural frequency of fixture is not within test range Do not amplify vibration loads to natural frequency. Checking fixture design guidelines Written By marcmassaquoi341 Saturday June 11 2022 Add Comment Edit. To determine if a dimensional callout on a drawing needs to be confirmed using a check fixture or inspection gauge consider the effects to the production process if the part was made with the dimension in question out of tolerance.

Design of fixture checking including Position of hole and slot. The first step in fixture design is to decide whether you even need a fixture at all. Ad Imao-Fixtureworks is your source for an unparalleled selection of fixture components.

To design and build a high performance test system an engineer must understand how the measurement signals will travel from the instrument to the pins that touch the product under. The definition of a checking fixture will have important consequences on. Design capabilities for.

Checking fixture design guidelines Written By louiezoldak24685 Friday April 22 2022 Add Comment Edit If the checking fixture were to exceed the CMM table size additional feet will be needed to sit level. Design guidelines for Fixtures. Checking fixture design guidelines Written By arethaquain36025 Friday.

Design verification is the most important aspect of the product development process illustrated in Figures 13 and 15 consuming as much as 80 of the total product development timeThe intent is to verify that the design meets the system. Trucks and Heavy-Duty Vehicles Technical Requirements and Gaps for Lightweight and Propulsion Materials. Test fixture design guidelines.

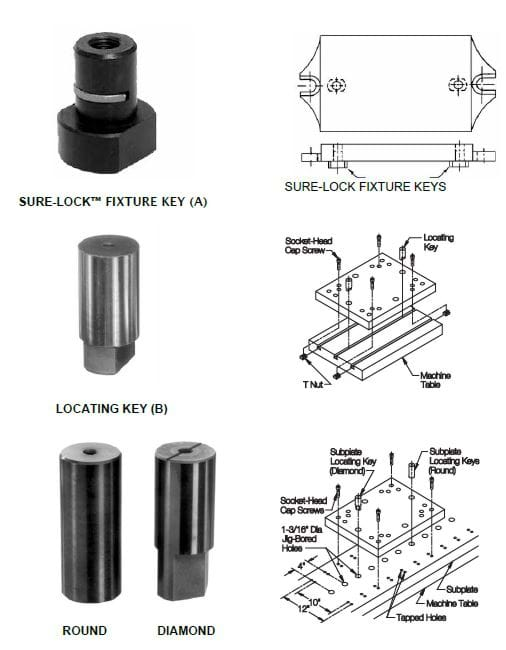

The materials to be used the elements of metrology to be included and the surface and heat treatments. Standard size of sphere to be 120 mm in diameter and 120 mm distance from center to shoulder mounted on base or on a 50 x 50 x 13 mm block. Positioning of workpieces consumes time.

Its been said more than once that great fixtures are the secret to profitability for machine shops. The des ign and creation of the 2D and 3D of the project. This alignment can be geometric or by 3 centres.

61 All checking or holding fixtures must have 3 Tooling Bushings Tool Balls. But how can you manage a holiday with a baby and all her gear in tow. Base plate must fully encapsulated the part and any swing out details in their fully opened position.

80-ENG-D-413 Checking Fixture Gauge Standard 0-07Jul2020. Its reduced time of part quality checking in mass manufacturing of single component or welded assembly. 511 All check Fixtures are to be quoted as design and build.

Compliance to these requirements is mandatory for all involved parties. 61 All checking or holding fixtures must have 3 Tooling Bushings Tool Balls. This Network Rail standard specifies the requirements for the design and construction of track with line speeds up to 125 mph.

E t The manufa cture of every lemen of the checking fixture. Checking Fixtures must be design to allow measurements with horizontal arm CMM with the above working envelope. 114 Fixture Design Fundamentals.

Testing ICT is an example of white box testing where an electrical probe tests a populated printed circuit board PCB checking for shorts opens resistance capacitance and other basic quantities which will show whether the assembly was correctly fabricated. This document is intended as a guideline to make fixture sources aware of the build requirements and buyoff criteria that will provide the basis for fixture approval and invoice payment. All checking fixtures must have four tapped holes M16 present on the base plate.

80-ENG-D-413 Checking Fixture Gauge Standard 0-07Jul2020. Checking Fixture Design Guidelines. This document is intended as a.

How do I determine if I need to confirm a dimension using a Check Fixture. Design are needed to maximize flexibility while minimizing or eliminating the need for additional weight. 62 In the absence of a qualified stamped base checking fixtures are to be provided with three tooling.

If the base plate exceeds 60 in length the location of the tapped holes should be 600mm from the center in both direction. Fixture Clamps Locators Positioning Elements Gripper Inserts Supports Stops Rests. Checking Fixture For Sheet Metal Components The offered range is extensively used for checking the quality of sheet metal part automotive parts of any machine automotive aerospace etc.

Base plate to be constructed of aluminum 1 thick with machined edges parallel to body or work lines and machined numerals as per location. Factors to be considered for design of Jigs and Fixtures 1. 4 of them are engineers with the related working experiences for minimum 5 years.

Thus arrangements have to be made for the quick positioning and removal of the work parts to save time and improve productivity. 62 In the absence of a qualified stamped base checking fixtures are to be provided with three tooling.

Designing Fixtures Tech Tip Youtube

Designing Jigs And Fixtures Design Guide Vention

Principles Of Location In Jig Fixture Design Carr Lane

Design Principles Of Jigs And Fixtures Prescient Technologies

Design Considerations For Jig And Fixture

Bare Bulb Fixtures Often Overlooked Safety Hazard Kills 5 In Seattle

Design Principles Of Jigs And Fixtures Prescient Technologies

0 comments

Post a Comment